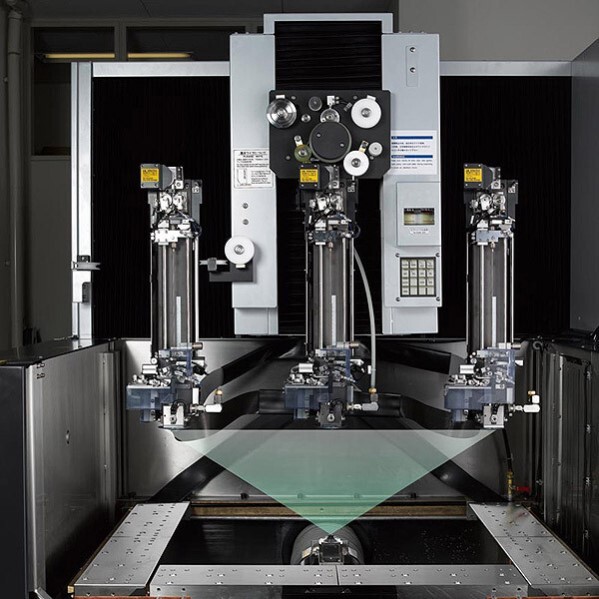

Large Sized, Taper Linear Motor, Premium Wire-Cut EDM Machine with Smart Linear Technology

AQ900L

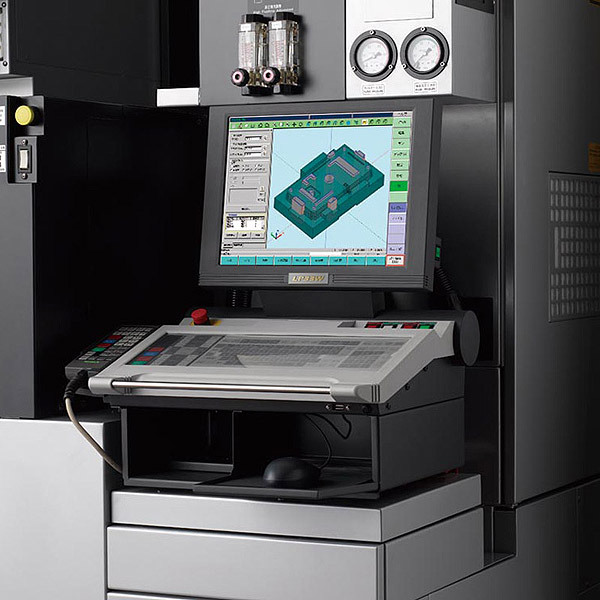

Large size wire cut EDM machine with all accuracy and quality you would expect from Sodick. High speed, precision and accuracy with linear motors plus LP control technology. Solid models can be directly imported maximising cutting efficiency, reducing work flow and programming errors.

In response to the growing demand for large dies spurred by the huge popularity of large screen TV's, the AQ900L Premium, also equipped with LP Power supply have been designed especially for machining large size dies for large size components as well as for automobile parts such as instruments, panels and bumpers.

| X/Y/Z Axis Travel (mm) | 900 x 600 x 400 |

| U/V Axis Travel (mm) | 920 x 620 |

| Machine Tool Dimensions (W x D x H, mm) | 2,380 x 3,150 x 2,395 |

| Maximum Workpiece Weight (kg) | 2,000 |

Features

- 10 year warranty on positioning accuracy

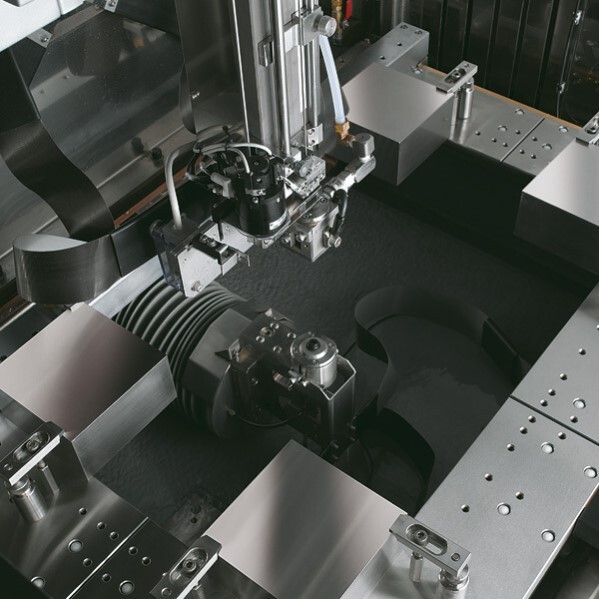

- Linear motor (X, Y, U, V axis)

- Linear glass scales (X, Y, U, V axis)

- Ceramic components

- Linear motor cooling unit

- LP2WH high speed generator

- Intelligent Q³vic EDW

- Remote controller

- Esprit CAM software offline (regional option)

- Automatic Tank Door

- Work stand bridge

- Improved Ease of Operation

- High speed electrolysis free circuit

- Energy saving circuit

- SODICK Fine Corner Control

- FTII (Fine pick-up function)

- Automatic water level control

- Super jet AWT (Automatic wire threader)

- Wire end remover

- Wire chopper

- Receiver for max. 20 kg wire coils

- Dielectric cooling unit

- Voltage stabiliser

- LAN interface

- 15" TFT screen

- Totalising hour metre

- Work light

- USB port

Options

- Taper flex 45 (for taper cutting up to 45°)

- Oscilloscope

- 6/8-axis simultaneous (factory option)

- Custom colour

- WS4P/5P rotary table (indexing or simultaneous movement)