AP250L Premium

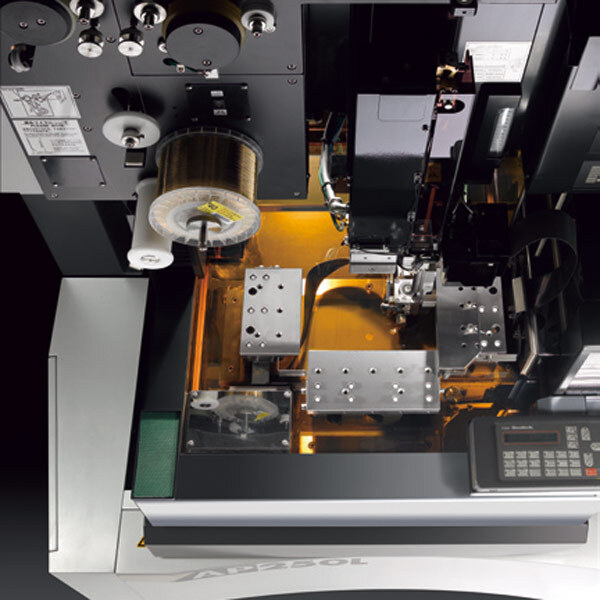

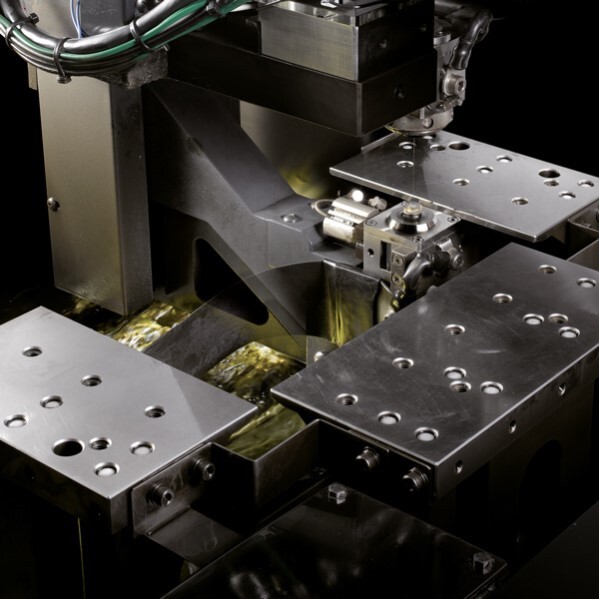

Linear Motor Drive System

Combination of linear motor drive system and a gantry structure has achieved great improvement of positioning and machining accuracy by taking full advantages of backlash free quick axis movement, while minimizing the deformation of the machine structure during axis movement. The new dielectric chiller and the surface level adjustment function ensure stable machining performance from the moment the machine is turned on.

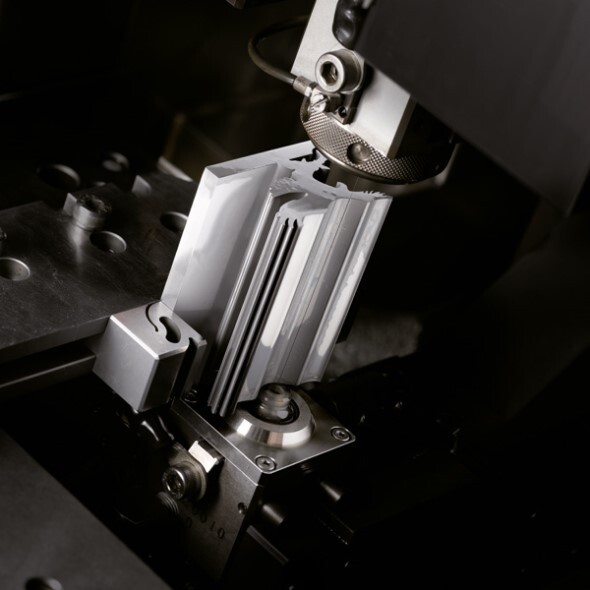

The New "SPW" Controller

The new generation electrical discharge technology "SPW" has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis-movements by using serial communication technology of 1Gbit/sec. The oil machine features Eco Cut O, which allows oil dielectric to realize a same cutting speed as water dielectric to achieve the surface finish of less than 0.15μmRa.

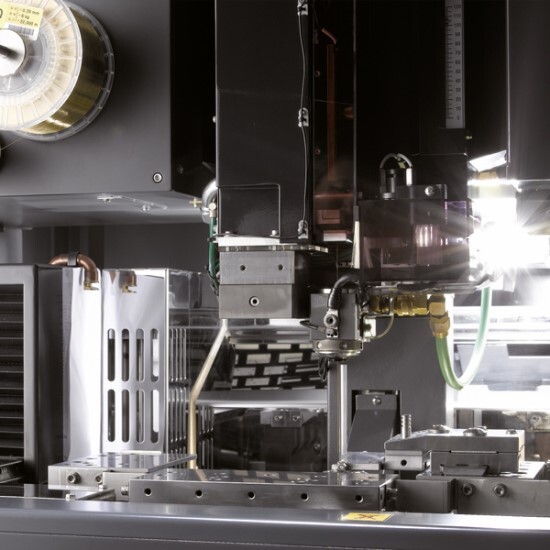

Improved Operability

The machine features 3-sided automatic tank door and a worktable with 3 frames to realize the user friendly operations. The optimum layout of a valve unit and a controller allows an operator to handle every work at the same place.

| X/Y/Z axis travel (mm): | 250 x 150 x 120 |

| U/V axis travel (mm): | 35 x 35 |

| Max. workpiece weight (kg): | 80 |

| Distance from floor to table top (mm): | 1080 |

Features

- 10 year warranty on positioning accuracy

- Taper cut unit

- Corner control

- Energy saving circuit

- Dieletric cooling unit

- AWT (Automatic Wire Threader)

- Super PIKA O

- Tension servo

- FT II (Fine Pick-up Function)

- Voltage stabilizer

- Active Power Restart (UPS)

- Linear scale (X,Y,U,V axis)

- Eco-Cut O

- Cross roller guides

- Linear Motor Drive (X, Y, U, V axes)

- Thermally stable machine construction

- SPW Power supply

- 3-sided automatic tank door

- Worktable with 3 frames

- Ceramic components

- Intelligent Q3vic EDW

- 1Gbit/sec communication technology

- LAN interface

- USB port

- 15" TFT screen

- Work light

Options

- 0.03mm wire (factory option)

- Jumbo feeder

- Oscilloscope

- Automation System: workpiece changer

- 6/8 axis simultaneous (factory option)

- Custom Color