K1C

Sodick’s K-series range of machines can produce very small holes quickly and efficiently.

The manually operated K1C model is ideally suited for the production of small diameter holes with a machining range of 0.25 to 3.0 mm diameter, particularly in materials which cannot be machined by traditional methods, and without high tooling cost.

| X/Y/Z axis travel (mm): | 200 x 300 x 300 |

| Table dimensions (W x D, mm): | 250 x 350 |

| Max. workpiece weight (kg): | 100 |

| Machine dimensions (W x D x H, mm): | 890 x 870 x 2015 |

Features

- Improved Ease of Operation

- Guide set 0.8 mm

- Electrode tube 20 pcs. 0.8 mm

- Splash guard

- Workpiece fixtures

Options

- High column spec. (100/200mm)

- 30-amp booster for electrode diameters up to 6.0 mm

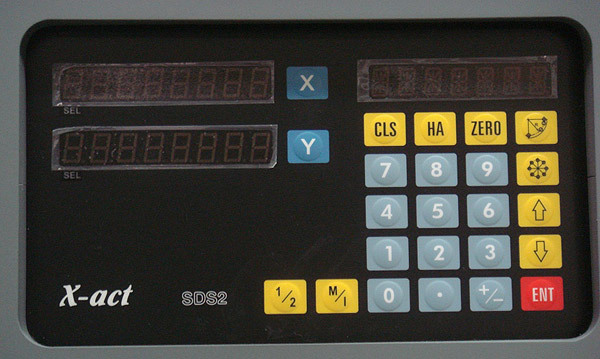

- Z axis digital

- Flush block

- 100-litre dielectric tank