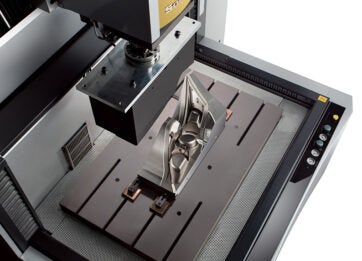

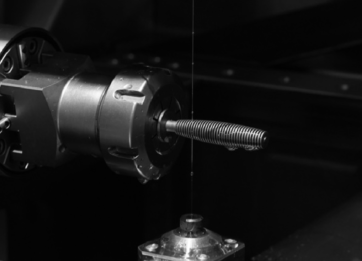

As an EDM pioneer, Sodick offers a wide range of linear EDM machines. High Speed Milling machines and EBM machines also feature in the Sodick product line up. More than 90% of all machine components including CNC and Linear motor are in-house developed by Sodick to ensure the highest quality.