Sodick proudly launches 2 new super-large linear machines: AQ1500L Premium Wire-Cut EDM and AQ20L Die-Sinker EDM for manufacturing large-size components. The machines come with all the latest Sodick in-house made technologies such as linear motors, ceramic components and ‘State of the Art’ communication technology of 1Gbit/sec to ensure the accuracy, quality and speed which customers would expect from the Sodick brand.

Sodick’s new Wire-Cut EDM AQ1500L Premium features linear motors on X, Y, U and V Axes. It is the world’s largest capacity linear motor drive wire-cut EDM. The machine has the axes strokes of 1,500 x 1,000 x 600mm (X x Y x Z) and the 4-sided frame work-table supports work-pieces of up to 1,600 x 1,200 x 400mm. A maximum 20kg Wire Bobbin can be utilized for extended un-manned production.

The AQ1500L also benefits from an ultra-high-rigidity structure thanks to a unique fixed table design and the integration of both electrical and mechanical equipment within a single unit. The automatic front tank door and wide open space allows easy access of a crane for loading of large work-pieces and user-friendly operation.

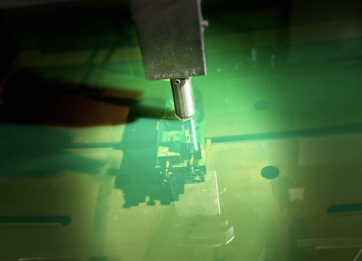

The AQ20L is now the world’s biggest linear EDM, with the axes stroke of 1,200 x 2,000 x 600mm (X x Y x Z). The machine work-tank is separated from machine unit; thanks to this innovative machine design, the weight of work-piece does not adversely affect the precision and speed of the Axis movements.

Linear motors on X, Y and Z Axes, communication technologies of 1Gbit/sec and the SGF “Nano Wear” generator realize high-speed and high-precision machining while minimizing the electrode wear at the same time resulting in lower running costs and higher production.

Both of the new models are suitable for industries such as Aerospace, Energy and Automotive where the demand for larger parts is continuing to grow.

The positioning accuracy of the Linear Motor Drives are guaranteed for 10 years on both models, so that customers can utilize the machine’s capabilities with confidence, knowing Sodick’s superior performance and their investment is assured for a long period of time.

For more technical details, please refer to the links below.