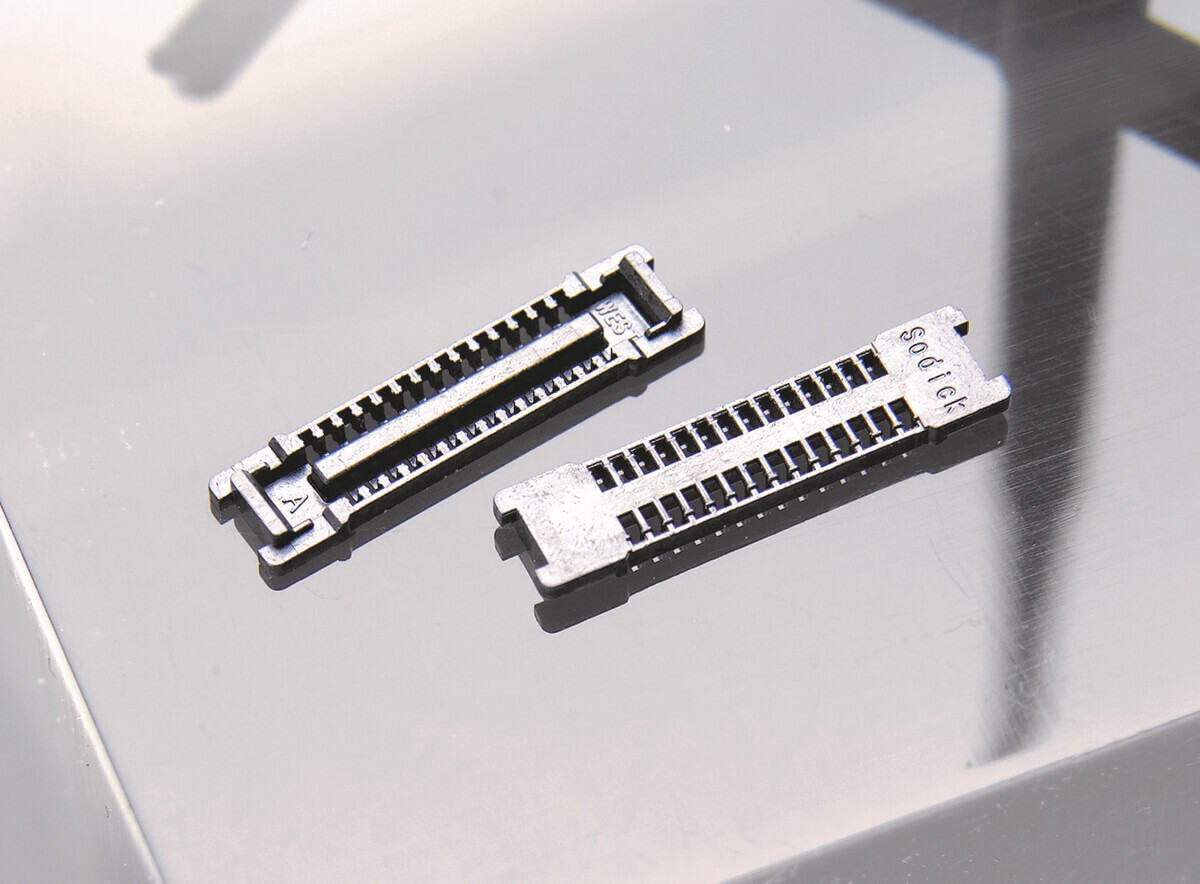

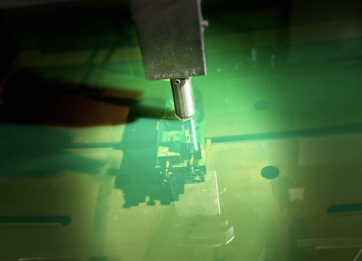

At K 2022, Sodick Europe will be demonstrating the 30-tonne hydraulic hybrid GL30 injection moulding machine - equipped with Sodick’s unique V-LINEÒ technology - ideally suited to the production of very small, complex, high precision, high value-added products, for example in the medical, electronic, and precision instrumentation sectors. On the stand the GL30 will be moulding 28-pin 0.35mm pitch micro connectors.

The GL30 will be utilising OPC UA communication tools to enable it to share data with other compatable machines, in accordance with the UMATI (Universal Machine Technology Interface) vision of increasing connectivity by the promotion and adoption of open, standardised interfaces. www.umati.org.

The small footprint GL30 provides users with enhanced stability, traceability, and usability, with a host of advanced injection moulding functions, as well as direct pressure mould clamping and Sodick’s new Total Servo Drive system to further improve operational accuracy and energy savings.

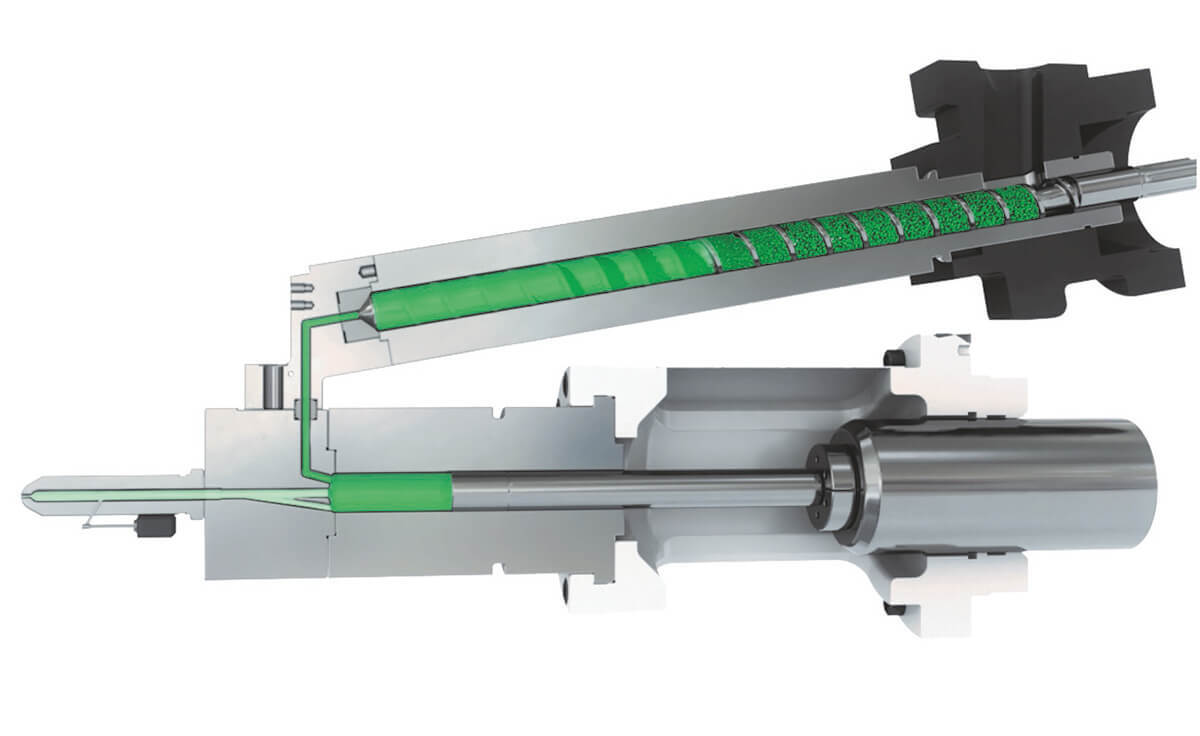

The concept behind the V-LINEÒ technology is to separate the injection and plasticization processes in one unit, resulting in extremely accurate, rapid, and repeatable resin injection; suppressing outgassing, reducing fibre fracture, and preventing backflow.

The V-LINEÒ technology ensures stability in three key areas, firstly in the melt condition of the resin, secondly in the density of weighed resin and thirdly in the true fill volume. These benefits are achieved using a Linear Servo Drive to control the low inertia plunger, providing rapid acceleration, sharp stopping, and accurate acceleration/deceleration.

The GL30 provides additional “green” efficiency benefits in terms of quick start to production, improved ratio of crushed and recycled material and mould damage prevention as well as increased plunger durability.

Also helping customers towards their aim of achieving defect-free production, the GL30 reduces sporadic and difficult-to-analyse defects in continuous moulding, prevents foreign matter contamination and material jamming, while also increasing stability of material feed.

Digital Images

Issued by:

SMPR Limited, Contact: Shelagh Morgan, Tel: 0777.5761553, shelagh.morgan@smpr.co.uk

On behalf of:

Sodick Europe, Agincourt Road, Warwick, CV34 6XZ, UK Tel. +44 (0)1926 695777