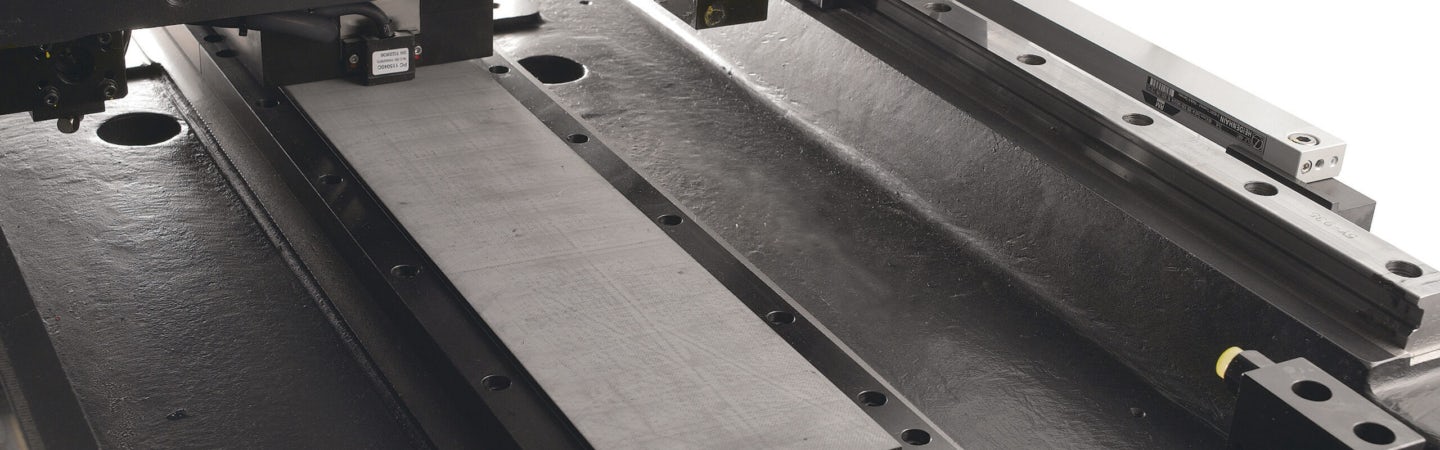

Linear motor axis drives (standard - X,Y,U,V axis)

Advantages of linear motor drives

- eliminates ball screw drives

- no back lash or lost motion

- best part geometry & finish with reduced skim passes

- fewer wire breaks

- increase cutting speed

- no maintenance

Don’t get ball screwed

Over time ball screws will wear, creating scrapped parts; but since linear motor drives eliminate the need for ball screws, they have also eliminated the possibility of scrap parts

How linear motor drives work

- Linear drives contain the same components as a servo motor (magnets & copper coils).

- A linear motor is an uncoiled servo motor.

- As amperage enters the coils, it creates force that is repelled against the magnets.

- The motor is also the driving force thus eliminating the need for a ball screw.

Linear motors = No Ball Screws

- worn ball screws can create scrapped parts & downtime

- ball screw replacement parts can cost as much as €5.000

- with linear motor drives you will never worry about this

Sodick Linear Motor Display

Sodick's linear motor's speed and acceleration are displayed in this video.

Sodick's Linear Motor Vibration Test

A nickel balances on the chuck (traveling at 1,400"/min) of a Sodick CNC sinker EDM.

Linear Motor and Ball Screw drive comparison

Animated comparison of a linear motor and ball screw drive.